Exploring the Frontier of Field Repairs

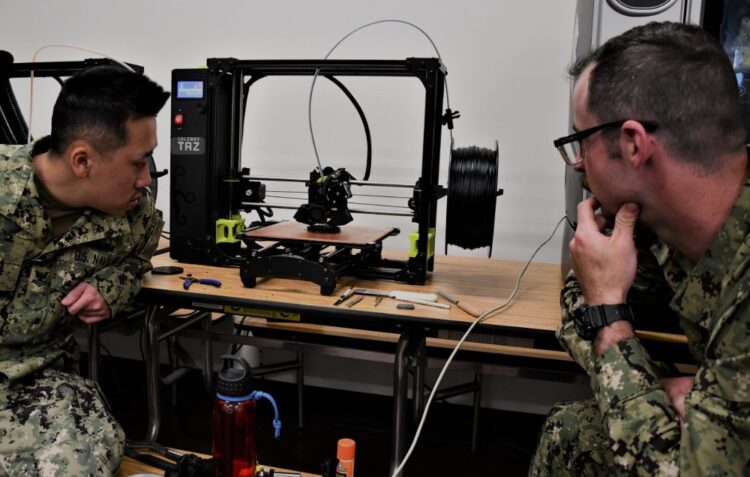

The US military has long been at the forefront of technological innovation, consistently seeking methods to improve efficiency and effectiveness. A notable advancement in this endeavor is the recent testing of forward-deployed 3D printers, primarily for repairing drones. These printers promise to revolutionize the repair operations of the armed forces, allowing quicker responses and reduced logistical footprints.

Technology Meets Battlefield Needs

3D printing, or additive manufacturing, enables the creation of three-dimensional objects by layering materials. For the military, this means on-site production of components that might otherwise require days or even weeks to procure from distant suppliers. The emphasis on drones comes as these unmanned aerial vehicles (UAVs) play crucial roles in reconnaissance, surveillance, and targeted operations. These machines, while sophisticated, are not immune to damage in the field. Having the capability to rapidly print parts on location ensures minimal downtime, keeping missions on track.

Advantages of 3D Printing on Deployment

- Efficiency and Speed: Manufacturing drone parts on the ground significantly reduces the time taken to replace or fix broken components. Traditional logistics involve tedious processes that can be circumvented with on-the-spot production.

- Cost-Effectiveness: With 3D printing, the cost of logistics and warehousing can be reduced. Instead of stocking various components, military bases can store digital files and raw materials.

- Customization and Flexibility: Field teams can innovate solutions by customizing parts according to specific mission needs. This adaptability is particularly crucial in dynamic combat situations where requirements can change rapidly.

Implementation Challenges

While the benefits are compelling, the implementation of forward-deployed 3D printers is not without its challenges. One primary concern is the durability and precision of the components made through this technology. Ensuring that printed parts stand up to the rigorous demands of military operations remains a significant hurdle.

Furthermore, the current generation of 3D printers might struggle with the complexities involved in producing certain advanced drone parts that require high precision and specialized materials. This technological gap necessitates concurrent advancements in both printing technology and materials science.

Operational Security Considerations

The integration of 3D printing into military operations also poses security concerns. Digital blueprints for drone parts must be stringently protected against cyber threats. Breaches could lead to unauthorized access, potentially compromising mission integrity.

Collaborative Efforts and Investment

To tackle these challenges and optimize the technology’s potential, the Department of Defense has been collaborating with leading aerospace firms, technology companies, and academic institutions. Test programs have been established at various military bases to assess the viability of different 3D printing systems. Increased investment in research and development is key to refining this technology for more robust field applications.

A Glimpse at the Specs

| Printer Model | Material Compatibility | Printing Speed | Resolution |

|---|---|---|---|

| Stratasys F900 | Thermoplastics, Composite Filaments | Up to 200 mm/sec | Up to 30 microns |

| Markforged X7 | Onyx, Carbon Fiber | Up to 200 mm/sec | Up to 50 microns |

The Future of Military Logistics

As forward-deployed 3D printers become more sophisticated, they are likely to transform not only how the military conducts field repairs but also how inventory and supply chains are managed. The future might see further miniaturization of these devices, making them even more portable and efficient. Furthermore, as material technology advances, the range of components that can be recreated in the field expands, further negating the need for exhaustive spare part inventories.

The vision of a fully integrated battlefield where technology seamlessly supports operational needs is gradually becoming reality with such innovations. Continued experimentation and adaptation will undoubtedly enhance the military’s capabilities, providing strategic advantages in various conflict scenarios.

The military’s adoption of forward-deployed 3D printing exemplifies a broader trend towards efficiency and innovation. While challenges remain, the potential benefits of such a transformative approach are boundless, paving the way for a future where logistical constraints are drastically minimized.